Coconut Milk Processing Machine

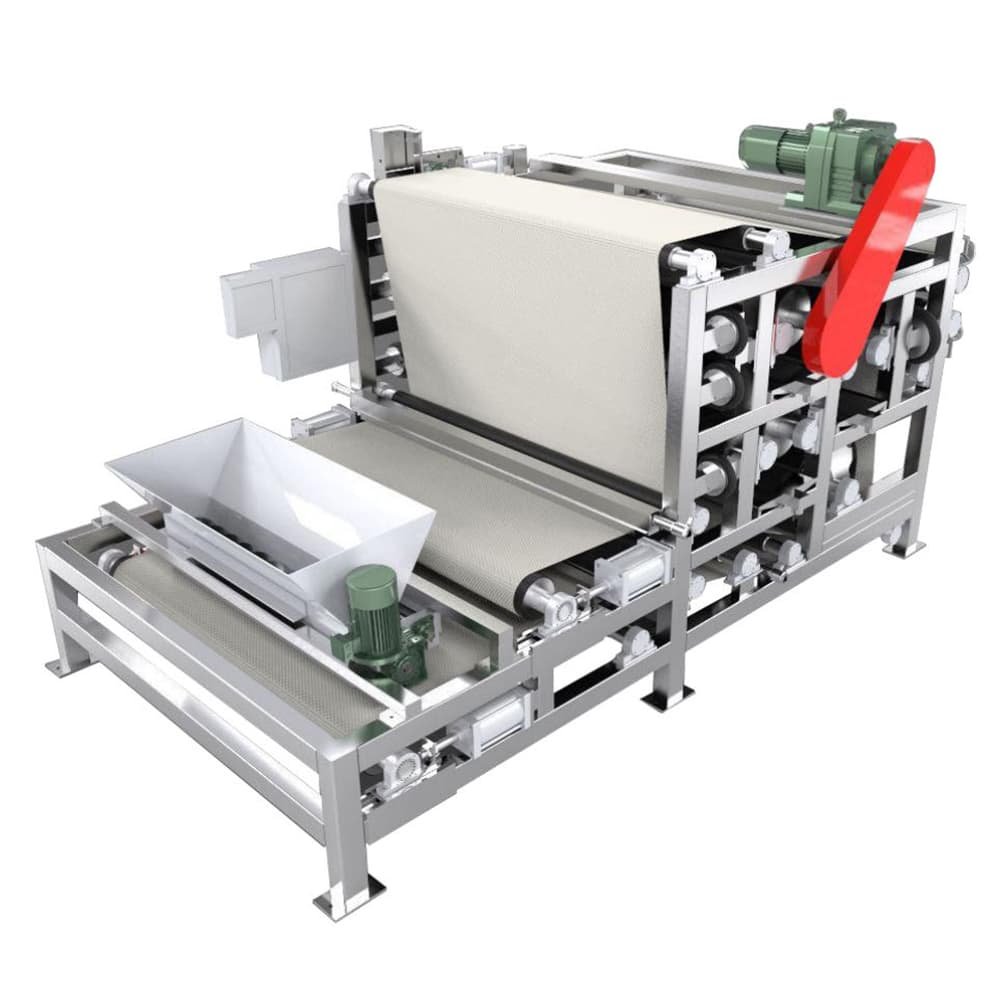

Coconut milk processing machine is equipment designed to obtain milk from the meat of coconut. Belt filter press is used for large-scale coconut factories.

Coconut Milk Processing Machine Introduction

Its popularity in food, beverages, cosmetics, and medicine imposes a good and clean processing requirement on the part of coconut milk. These machines help ensure that production is smooth and that key steps like extraction, separation, and filtration are automated. This reduces the need for manual labor and improves the product quality.

How a Coconut Milk Processing Machine Works

The machine for processing coconut milk goes through several steps to get coconut milk in an effective way.

Coconut Dehusking and Shelling:

Well, first, they strip off the outer covering of the coconuts and then remove the hard shell to get the white kernel or meat.

Grating or Grinding Coconut Meat:

The coconut kernel must be grated or crushed into small pieces in order to extract the most milk from it. Most of this is done by use of grating machinery or a hammer mill.

Milk Extraction Process:

Next, the milk-extracting machine is used on the grated coconut meat. Such a machine could be a hydraulic press, screw press, or centrifugal extractor. Others use warm water to aid in the extraction of more milk.

Filtration and Separation:

After pressing, the fresh coconut milk is filtered through fine mesh to separate any solids. Modern machinery include separators that split the coconut cream and the lighter milk.

Homogenization and Pasteurization:

That way, the milk will be homogeneous, not separated when stored, and will be pasteurized to make it safe for consumption and to prolong shelf life.

Packaging:

From here, automated filling units package the coconut milk into bottles, cans, or pouches, sealing them airtight for freshness.

Types of coconut milk making machines.

Small Machines: They are good for local businesses, farmers, or small food makers. These machines are small in size and easy to use, besides producing less.

Medium- to Large-Scale Machines: These are designed for industrial production and are automated to handle large amounts of work effectively.

Screw Press Extractors: These are generally in large plants and extract milk by compressing grated coconut under high pressure.

Centrifugal Extractors: Applies high-speed revolutions in cream and milk separation.

Main Benefits of Using a Coconut Milk Processing Machine

Increased Efficiency: Mechanization in the process of extraction reduces manual labor and increases production speed, making large-scale manufacturing viable.

Improved Product Quality: Consistent processing and filtration ensures high-quality, smooth-textured milk without contamination.

Less waste: More efficient machines get more milk out of the same coconut, leaving less to be thrown away.

Hygienic Processing: Stainless steel design and cleaning systems provide for production meeting food safety regulations.

Cost Savings: In the long run, automated processing reduces labor and downtime costs, maximizing profitability.

Applications of Machines for Coconut Milk Processing

Food Industry: To produce beverages from the coconut, desserts, ice creams, and curry pastes.

Cosmetics and Pharmaceutical Industry: Coconut milk is an essential component in manufacturing beauty products and herbal supplements.

Dairy Industry: Plant-based milk manufacturers utilize these machines to process coconut milk as opposed to dairy.