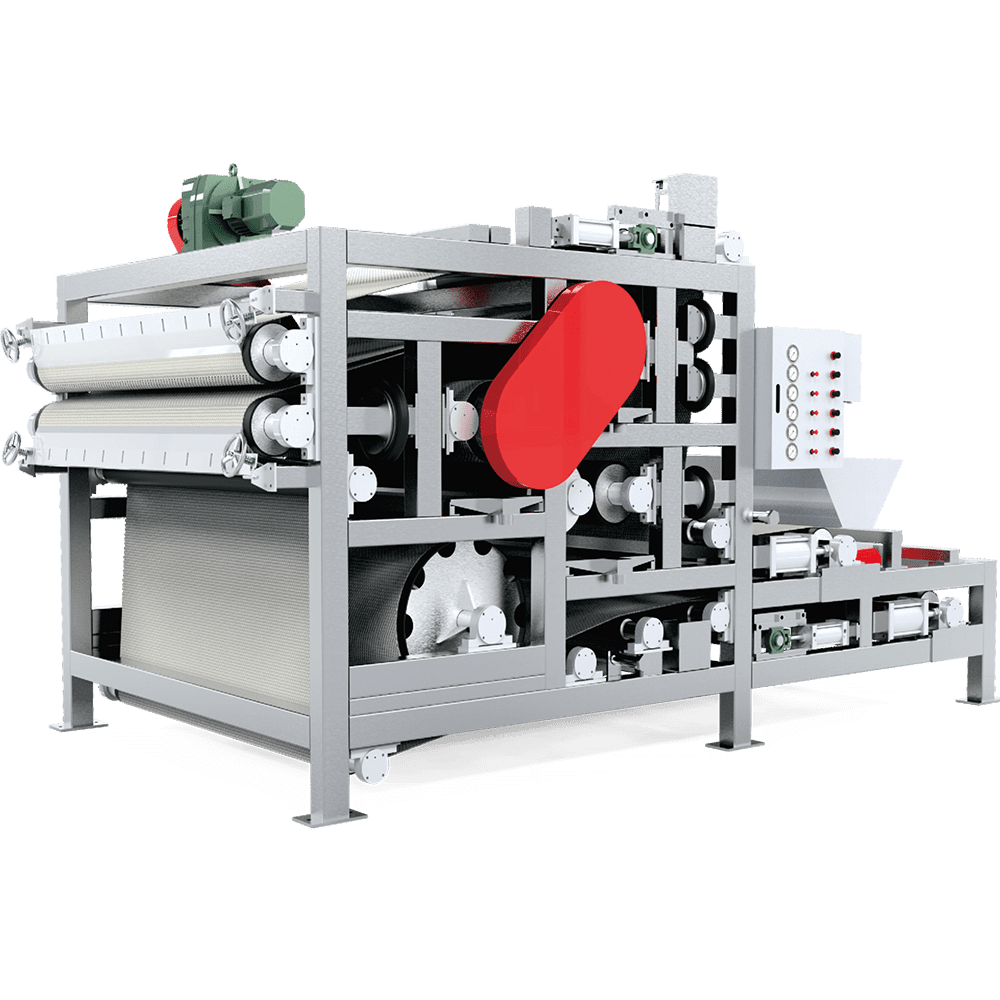

Belt Filter Press

Belt Filter Press is a dewatering machine that separates liquids from solids. We use it to dewater residue, fiber, waste, spent, dreg, pulp, sludge.

Applications Of Belt Filter Press

Belt filter press, sometimes called belt press or belt filter, is an industrial machine for solid/liquid separation. Particularly for the dewatering of sludges in the food industry, mining and water treatment.

Sludge dewatering

Of sludge for example food waste, cutting

base paper pulp and organic matter-based wastes byproduct, bark slag, farm

residues, bears spent, tailings, corn dregs. Water is extracted from the sludge,

which then becomes suitable for waste management (as used in agriculture or as

fertlizer).

Wastewater treatment

Municipal wastewater (houses, sinks,

showers and washing machines) Also from industrial effluents including heavy

metals, organic and oils, suspended solids etc. Proper wastewater management is

important to conserve the environment and precious water resources.

Sludge Dewatering

Dewater sludge from wastewater treatment plants, and the residual material left after certain industrial processes (such as food manufacturing, mining or paper industries).

How does a belt filter press work?

Feed Stage: The feeding device evenly distributes the sludge onto the moving belts.

Gravity Drainage: After passing through a number of rollers that follow its movement over the porous belt, gravity first removes free water from the sludge.

Pressure Filtration: The sludge is fed between two porous belts, then passes an array of high pressure rollers. The water permeates these belts and then leave solid particles that form a cake on the belt.

Cake Discharge: The cake which has been formed is then scraped from the belt and discharged for either further use or waste.

Belt Washing: While in operation, after cake discharge, washing the belts to clean off any remaining solids and recondition them for their next cycle.